Mesin Sublim Valuejet 1948WX

ValueJet 1948WX mesin sublim large-format dari MUTOH yang dirancang untuk produksi tekstil dan printing massal dengan performa tinggi. Dengan lebar media hingga 1910 mm (75”) dan sistem 4 print head staggered, printer ini mampu menghasilkan cetakan besar dengan kecepatan hingga 117.3 m²/jam, ideal untuk kain roll, wallpaper, home textiles, spanduk, dekorasi, dan berbagai aplikasi tekstil profesional.

mesin yang menggunakan tinta sublimasi khas MUTOH, serta dilengkapi dengan dual-heater built-in, sistem feed & take-up heavy-duty, dan opsi cetak resolusi tinggi.

Keunggulan Utama

- Lebar Cetak Maksimal 1910 mm: cocok untuk printing kain lebar, wallpaper, spanduk, dan material besar.

- 4 Print Head Staggered + Variable Dot Technology: cetakan detail tinggi, warna kaya, dan kualitas profesional meskipun dengan kecepatan tinggi.

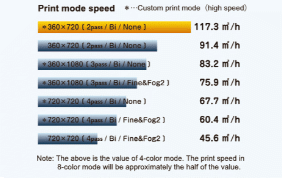

- Kecepatan Produksi Hingga 117.3 m²/jam (atau hingga ~195 m²/jam pada setting low-res): ideal untuk produksi massal dan pengerjaan cepat.

- Built-in Dual Heaters & Sistem Drying Cepat: mempercepat proses, mengurangi waktu tunggu, dan mempercepat throughput produksi.

- Feed & Take-Up System Heavy-Duty (hingga 100 kg roll): stabilitas media saat produksi roll-to-roll, cocok untuk volume besar dan kain panjang.

- Kompatibilitas Media & Tinta Sublimasi Water-Based: cocok untuk tekstil polyester, kain fashion, dekorasi interior, home textile, dan sebagainya.

- Fleksibilitas Warna: 4-Color & 7-Color memungkinkan gamut warna luas dan hasil gradasi halus untuk desain kompleks.

Fitur:

- Tinta sublimasi MUTOH “DH21”

- Empat kepala cetak berjenjang

- Teknologi Titik Variabel

- Penyesuaian ketinggian kepala dalam 3 langkah

- Pemanas ganda berukuran besar yang terintegrasi

- Sistem rol tekanan bawah

- Dilengkapi dengan fungsi pemotongan otomatis

- Sistem pengumpanan dan pengambilan termasuk (hingga 100 kg)

- Perawatan harian yang mudah

Aplikasi:

Banners

Signage

Sticker

Table Display

Window Decals

Wraps

Konfigurasi 4 printhead bertingkat yang mengoptimalkan kecepatan dan kualitas cetak

Desain 4 kepala cetak yang berjenjang memungkinkan pencetakan berkecepatan tinggi dan peningkatan produktivitas. VJ-1948WX mencapai kecepatan cetak maksimum 17,3 m² per jam. Fungsi pemilihan kepala cetak tersedia untuk dicetak. Tanpa menggunakan kepala cetak yang rusak, printer tetap mencetak menggunakan kepala cetak yang tersisa, dan memberikan dukungan bisnis yang andal. Selain itu, VJ-1948WX meminimalkan konsumsi tinta dengan memilih kepala cetak untuk melakukan pembersihan kepala cetak.

Pemanas ganda berukuran besar yang terintegrasi

Pemanas ganda berukuran besar yang terintegrasi menyediakan waktu pengeringan yang cepat untuk meningkatkan kecepatan produksi.

Mereka terpasang di bagian belakang panduan kertas depan. Suhu setiap pemanas dapat diatur secara individual melalui panel kontrol, dan dapat diperiksa atau diubah kapan saja tanpa mengganggu proses pencetakan.

Sistem pengambilan beban berat termasuk dalam paket

Sistem pengumpanan dan pengambilan berkapasitas tinggi menjaga transportasi media yang stabil hingga 100 kg. Sistem ini juga mendukung kertas transfer standar 70 gsm/m² hingga kertas transfer yang lebih tebal dan berat dengan ketebalan 130 gsm/m². Bahkan kertas transfer sangat tipis dengan ketebalan 45 gsm/m² dapat didukung dengan mengatur kondisi berat, pengaturan anti-kerutan, kipas adsorpsi, dan sebagainya.

Karena media cetak digulung dengan tekanan konstan, media tersebut dapat digunakan dengan mudah pada tahap pemrosesan panas setelah pencetakan.

*Sistem ini juga dapat dipasang pada VJ-1948WX sebagai opsi.

Kualitas gambar tinggi dengan teknologi titik variabel

Tiga jenis titik variabel menghasilkan tekstur halus dan reproduksi warna yang baik. Dengan menggunakan diameter yang berbeda-beda, yaitu besar, sedang, dan kecil, mereka dapat mengekspresikan gradasi warna secara halus dan warna yang cerah.

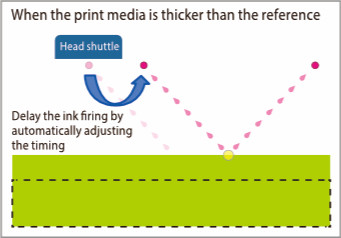

Teknologi DropMaster

By inputing different media thickness on the registered media setting, Drop Master Technology is capable of automatically recalculating and adjusting the bi-directional drop fire timings. It achieves smooth high-quality printing.

Teknologi Interweave Pintar

Teknologi interweave cerdas menawarkan berbagai efek cetak untuk meningkatkan kualitas gambar. Teknologi ini memungkinkan pengurangan dan eliminasi pola garis (banding) serta ketidakmerataan warna.

*Efek ini mungkin tidak cocok untuk pencetakan berkecepatan tinggi. Silakan lakukan uji coba terlebih dahulu.

Wave Print

Fuzz Print

Dirancang dengan fitur-fitur canggih

- Sistem penahan rol tekanan terpasang di bagian depan dan belakang printer, dan memastikan pengoperasian yang mudah melalui tuas manual dari salah satu dari dua lokasi. Terdapat dua pengaturan tekanan, yaitu “standar” dan “kuat”.

- Rol tekanan dapat dinaikkan dan diturunkan secara individual bahkan saat mencetak pada kertas transfer tipis untuk menghindari kerutan.

The head height can be adjusted in three steps : 1.5mm, 2.5mm, and 4.0mm. Each can also be activated for auto-cleaning.

MUTOH Status Monitor (MSM)

- Peningkatan signifikan dalam waktu respons untuk pengambilan status cetak

- Dukungan untuk panduan instalasi awal

- Dukungan untuk 10 bahasa untuk semua fungsi.

It requires user registration to download MSM.

https://club.mutoh.co.jp/mutoh/guser/

Specifications

| Model Name | VJ-1948 WX | |

|---|---|---|

| Print Technology | Drop-on-demand Micro Piezo Inkjet Technology | |

| Print Head | 4 (staggered setup) | |

| Head Heights | Low:1.5mm / Middle:2.5mm / High: 4.0mm | |

| Max. Media Width | 1910mm | |

| Max. Print Width | 1900mm | |

| Ink | Type | Water-based dye sublimation ink (NT Ink) |

| Ink set | 4-color (Black, Cyan, Magenta, Yellow) 7-color (Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta, Light Black) | |

| Volume | 1,000ml bottle | |

| No. of slot | 8 | |

| Print Resolutions | 1440/1080/720/360dpi (10 modes as standard + 19 modes as custom) | |

| Interface | Gigabit-Ethernet(1000BASE-T) | |

| Media Measurements* | φ150mm/ 2″ & 3″ / 30kg or less | |

| Heater Control System | Heaters(30-50℃), OFF | |

| Power Supply | AC 100-120V/AC 200-240V – 60/50 Hz | |

| A-property Acoustic Power Level (Actual Measured Value) | 69.8dB or less | |

| Printer Accuracy Guaranteed Environment | Temperature: 20~30℃ Humidity: 40~60%RH (Non Condensing) | |

| Power Consumption | Operating Status:600W or less, In standby: 91W or less | |

| Machine Measurements | W2983 x D966 x H1261mm (including a stand) | |

| W2983 x D1334 x H1261 mm (including a stand + feed and take-up system) | ||

| Packing Size | Printer: W3165 x D1150 x H900mm, Weight: 268kg | |

| Stand: W2462 x D395 x H250mm, Weight: 42kg | ||

| Feed and take-up system (100kg): W2780 x D1080 x H433mm, Weight: 159kg | ||

| Weight | printer: 164kg Stand: 37kg Feed and take-up system: 89kg | |

| Optional | Feed and take-up sysetem VJ-19TUP100 (100kg) | |

| Take-up system VJ-16/19TUP30 (30kg) | ||

| 1000ml/2200ml ink bag case | ||

| Cutter blade VJ-CB | ||

*Due to the removal of the flange joint, the 2-inch media core can be adjusted; however, do not use the solid 2-inch core media.