Xpertjet 1341SR Pro

High productivity and print quality remarkable cost performance

The XpertJet 1341SR Pro brings the best “Made in Japan Quality” to various markets such as banners, trade show graphics, indoor and out door signs, POP displays, vehicle wrap and more.

Features:

- MUTOH’s new print head “AccuFine” on board

- Productivity comparison with conventional printer

- Precise ink dot placement

- New print effect “i-screen”

- MUTOH’s genuine RIP software “VerteLith” optimizes the performance of the XperJet 1341SR Pro

- MUTOH Clear Tone Original half tone technology

- MUTOH CMYK Wide color gamut profile

- Accurately process PDF transparencies

- Automatic Bi-D adjustment ”DropMaster 2″Media feed flange

- Automatic media feed adjustment ”FEED MASTER”

- Nozzle selection Function ”Nozzle Area Select”

- Media roll balance management ”Media Tracker”

- Three head height settings

- Partial pressure cancel mechanism

- Media feeding and take-up units

- Edge holder

Application:

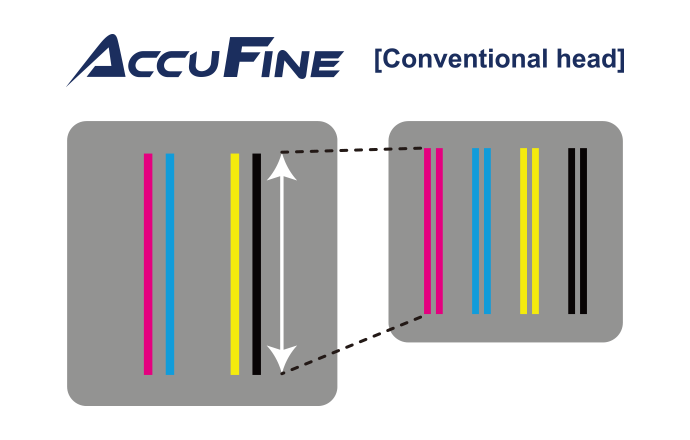

MUTOH’s new print head ”AccuFine” on board

The “AccuFine” is wider and delivers higher density with more accuracy than conventional print heads achieving both high-speed printing and excellent image quality. Even at high speed, the “AccuFine” can produce high-quality solid printing with less banding.

Increased nozzle row length

Contributes to higher productivity

*This is different from the actual ink arrangement.

High density nozzle pitch

Contributes to higher image quality

◆Productivity comparison with conventional printer

It achieves more than 200% productivity over conventional model in the same level of image quality.

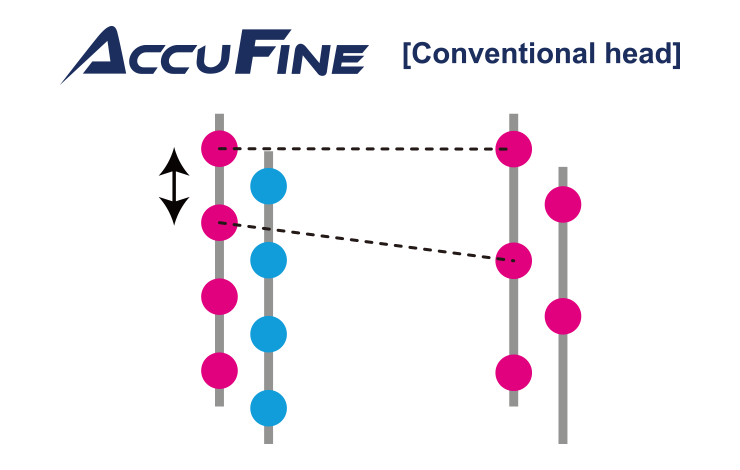

◆Precise ink dot placement

The integration of three features enables high quality printing.

High quality printing

“i-screen” and “TOPAZ RIP1” achieve

New print effect “i-screen”

The new print effect “i-screen” created from MUTOH’s “Intelligent Interweave” printing technology, optimizes the new print head “AccuFine”. By arranging the dots in a way that takes into account how they look, this reduces banding for smoother print images.

MUTOH’s genuine RIP software “TOPAZ Rip X1” optimizes the performace of the XpertJet 1341SR Pro

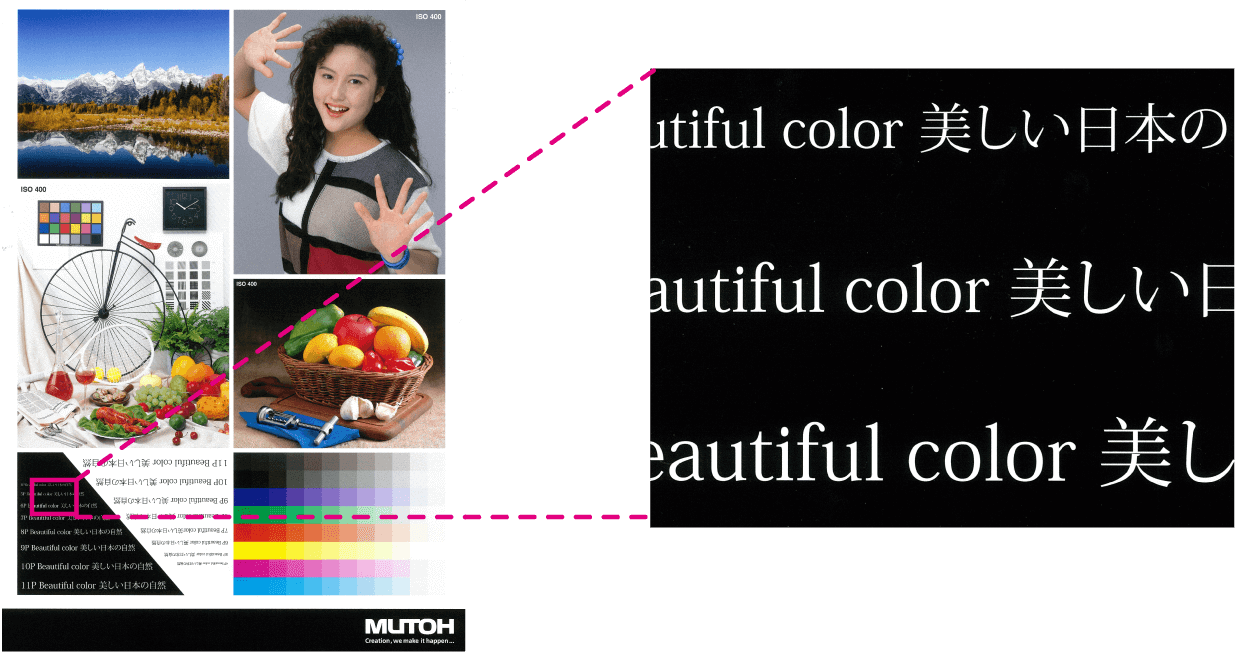

MUTOH Clear Tone

Original half tone technology

Less variation in color density and smoother gradations ———–

MUTOH CMYK

Wide color gamut profile

ICC INPUT PROFILE “MUTOH CMYK” maximizes the coverage of color gamut

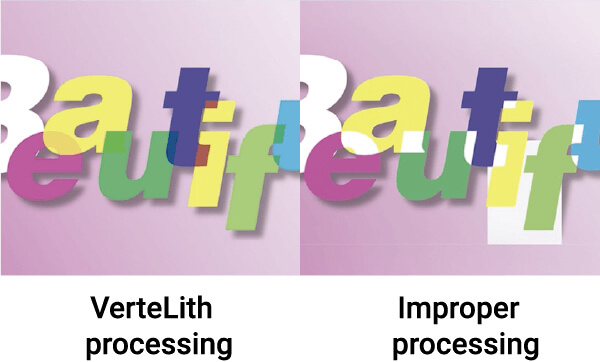

Accurately process PDF

transparencies

More reliable output by accurate processing of PDF transparencies & drop shadows

MUTOH’s unique technologies for automation and efficiency

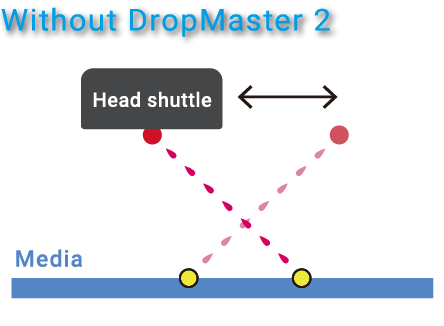

Automatic Bi-D adjustment

“DropMaster 2”

Automatic media feed adjustment

“FEED MASTER”

Nozzle selection Function

“Nozzle Area Select”

Media roll balance management

“Media Tracker”

High media compatibility

Three head height settings

High 2.5mm

Mid 2.0mm

Low 1.5mm

Partial pressure cancel mechanism

Media feeding and take-up units

Take-up unit

Media holder

Edge holder

Enhanced maintenance

MUTOH Status Monitor(MSM)

In the Status Monitor, the following information can be checked for the MUTOH printer.

■ Detailed information

■ Status information

■ Heater information

■ Head temperature/cartridge information

■ S/C card information

■ Paper information

■ Print information

■ Print history, etc.

■ Multi-language support for all functions (10 languages)

■ Print history can be exported as a CSV file.

Specifications

| Printer model | XPJ-1341SR Pro | |

|---|---|---|

| Print head | Print method | On-demand piezo drive system |

| Head height | Low:1.5mm / Middle: 2.0mm / High: 2.5mm | |

| Number | 1 | |

| Media | Roll media width | Maximum: 1,371mm Minimum: 500mm |

| Maximum media thickness | 0.3mm (the head height is set to Low), 0.8mm (the head height is set to Mid), 1.3mm (the head height is set to High) | |

| Diameter | Φ150 mm or less | |

| Core diameter | 2 inches or 3 inches | |

| Weight | 19kg or less | |

| Maximum printable width | 1,361mm | |

| Maximum print length | 200m | |

| Ink | Type | NT Ink 6000 SB |

| Color | 4-Color (Black, Cyan, Magenta, Yellow) | |

| Amount | 1,000ml bag | |

| Print resolution | Maximum 1200dpi | |

| Interface | Ethernet(10BASE-T / 100BASE-TX) | |

| Power supply | Voltage: AC 100V~120V ±10% / AC 200V~240V ±10% Frequency: 50/60Hz ±1Hz | |

| Environmental condition | Printer Operation | Temperature: 20℃~32℃ Humidity: 40%~60% No condensing |

| Accuracy Guaranteed | Temperature: 22℃~30℃ Humidity: 40%~60% No condensing | |

| Power consumption | Operation | AC100V~120V/AC200V~240V, 1560W or less (with heater ON) |

| Sleed mode | AC100V~120V/AC200V~240V: 21W or less | |

| External dimensions (W)x(D)x(H) | Printer mounted on stand:1,916mm x 685mm x 1,218mm (when cover closed) | |

| Weight | 86.0 kg (printer: 66.0kg Stand: 20.0kg) | |

| RIP software | Topaz RIP X1 | |