Mesin Eco Solvent Xpertjet 1682SR Pro

Deskripsi

Mesin Eco Solvent XpertJet 1682SR Pro adalah printer profesional dari Mutoh yang dirancang untuk memenuhi kebutuhan produksi tekstil berkecepatan tinggi dengan kualitas cetak premium. Dengan lebar cetak 64 inci, mesin ini sangat ideal untuk bisnis fashion, jersey, pakaian olahraga, dekorasi interior, spanduk, hingga kebutuhan produksi massal yang membutuhkan warna stabil dan detail tajam.

XpertJet 1682SR Pro dilengkapi dengan teknologi mutakhir dari Mutoh, termasuk printhead generasi terbaru yang mampu menghasilkan tetesan tinta presisi, sehingga kualitas gambar lebih halus, warna lebih hidup, dan gradiasi lebih konsisten. Teknologi Intelligent Interweaving (i²) pada mesin sublim ini membantu mengurangi banding dan menjaga hasil tetap stabil meskipun pada kecepatan tinggi.

Model Unggulan Seri XpertJet dengan Produktivitas Tinggi

XpertJet 1682SR Pro dilengkapi dengan dua unit “AccuFine HD” versi baru dari print head piezo ekstra lebar dan berdensitas tinggi “AccuFine” yang kini memiliki lebih banyak nozzle. Dibandingkan dengan model konvensional, XpertJet 1682SR Pro mampu mencetak hingga 189%* lebih cepat.

Selain itu, model ini mewarisi platform yang dirancang untuk meningkatkan kemudahan pengoperasian dan mengurangi beban kerja operator, serta dilengkapi dengan berbagai fungsi untuk memberikan dukungan tinggi bagi pengguna. XpertJet 1682SR Pro adalah model flagship dari seri XpertJet yang menghadirkan “kualitas gambar tinggi” dan “produktivitas tinggi” dengan menggabungkan teknologi tradisional dan teknologi canggih yang unik dari MUTOH.

*Perbandingan antara mode High Quality baru dan mode Quality2 konvensional (konfigurasi 8 warna).

Tinta eco-solvent MS41 yang dipasangkan dengan printer ini unggul dalam reproduksi warna, ketahanan cuaca, dan kemudahan perawatan. Tinta ini telah tersertifikasi UL GREENGUARD Gold, membuatnya ramah lingkungan dan juga lebih ramah (aman) bagi operator.

XpertJet 1682SR Pro menghadirkan “Kualitas Buatan Jepang” terbaik untuk berbagai pasar seperti spanduk, grafis pameran (trade show), signage indoor dan outdoor, POP display, branding kendaraan (vehicle wrap), dan banyak lagi.

Aplikasi:

Media Promosi Luar Ruang

Display Pameran

Stiker Dinding

Banner

Stiker

Branding Mobil

Dual head AccuFine HD menghasilkan produktivitas tinggi

For further high productivity

Up to 179% productivity compared to conventional model

For further high productivity

Hingga 179% lebih produktif dibanding model konvensional

Konfigurasi 8 warna ini memadukan “gradasi alami dan halus” dari tinta light dengan “ekspresi kaya” dan “reproduksi warna yang cerah” dari warna-warna hangat berkat tambahan tinta oranye. Hasilnya adalah cetakan yang memiliki “keindahan” sekaligus “dampak kuat”, ideal untuk Sign & Graphics.

Tinta oranye memperluas gamut warna untuk ekspresi yang kaya

Warna yang lebih jernih dan lebih hidup

*Gambar hanya sebagai ilustrasi. Hasil cetak yang sebenarnya dapat berbeda

Tinta Eco-Solvent MUTOH MS 41

Fitur Utama

- Menghasilkan gamut warna yang luas.

- Dot gain yang lebih baik di area berdensitas tinggi.

- Masa simpan 2 tahun (2 tahun setelah tanggal produksi).

- Ketahanan cuaca (3 tahun), ketahanan abrasi, dan ketahanan kimia yang sangat baik.

*Tinta oranye akan bertahan 3,8 tahun dengan laminasi dan 1,3 tahun tanpa laminasi. - Kemudahan perawatan

UL

GREENGUARD Gold

Certification

Kombinasi antara teknologi tradisional MUTOH dan teknologi terbaru

Presisi Cetak Tinggi

Struktur Rel Aluminium Berpresisi Tinggi: Teknologi tradisional khas MUTOH yang terbukti menghasilkan presisi cetak terbaik

Kualitas Cetak Tinggi

Perpaduan Teknologi Canggih (AccuFine, i-screen, VerteLith): Menghasilkan kualitas gambar superior dan produktivitas tinggi.

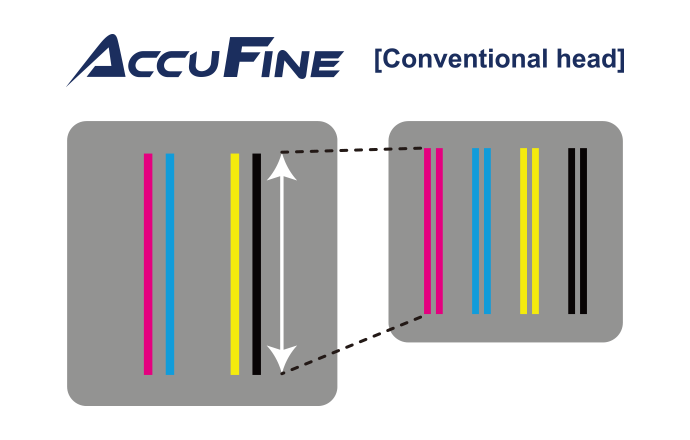

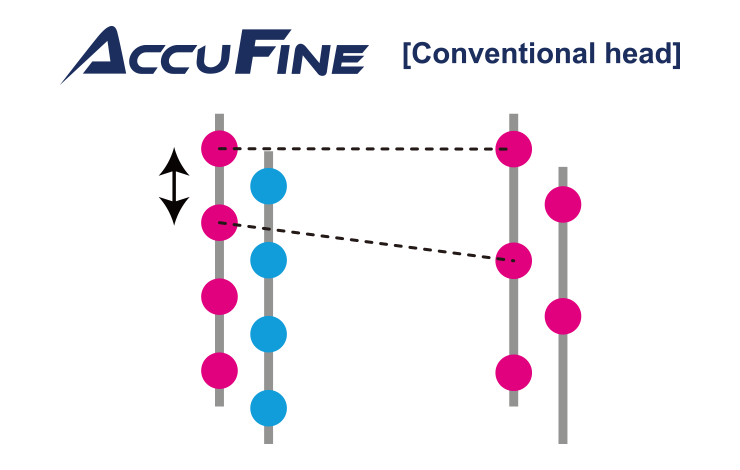

Dilengkapi dengan print head baru MUTOH ”AccuFine”

Panjang baris nozzle yang ditingkatkan

Menghasilkan produktivitas yang lebih tinggi

Kepadatan Nozzle Tinggi

Menghasilkan kualitas gambar yang lebih superior

Efek Cetak Baru “i-screen”

Teknologi “i-screen” diciptakan dengan mengoptimalkan “AccuFine” dan merupakan pengembangan dari teknologi cetak “Intelligent Interweave” milik MUTOH. Dengan menyusun titik-titik tinta berdasarkan tampilan visualnya, teknologi ini mengurangi banding untuk menghasilkan gambar cetak yang lebih halus

Software RIP orisinal MUTOH, “TOPAZ Rip X1”, mengoptimalkan performa XpertJet 1682SR Pro

MUTOH Clear Tone

Teknologi half tone orisinal

Variasi kepadatan warna yang lebih sedikit dan gradasi yang lebih halus

MUTOH CMYK

Profil gamut warna yang luas

Profil Input ICC “MUTOH CMYK” memaksimalkan cakupan gamut warna

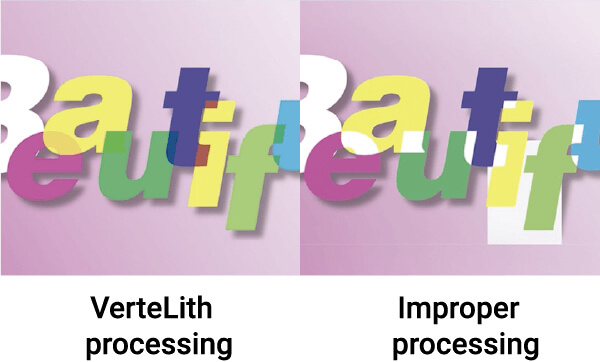

Memproses transparansi PDF secara akurat

Hasil cetak yang lebih andal berkat pemrosesan transparansi PDF dan drop shadow yang akurat

Teknologi unik MUTOH untuk otomatisasi dan efisiensi

Penyesuaian Bi-Direksional Otomatis

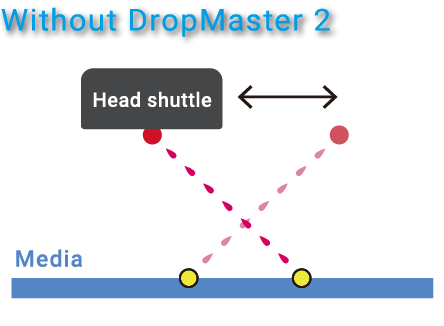

“DropMaster 2”

Sensor internal pada carriage secara otomatis mengkalibrasi penyelarasan bi-direksional, sehingga menghemat waktu dan mengurangi kebutuhan pengecekan penyesuaian antar operator yang berbeda

Penyesuaian Umpan Media Otomatis

“FEED MASTER”

Dengan mencetak pola cetak dan membacanya menggunakan sensor, koreksi pasokan media dapat dilakukan secara otomatis. Hal ini mengurangi waktu dan upaya yang diperlukan untuk penyesuaian, serta meminimalkan media yang terbuang

Fungsi Pemilihan Nozzle

“Nozzle Area Select”

Fitur “Nozzle Area Select” memungkinkan pencetakan berlanjut untuk sementara waktu dengan menggunakan area nozzle lain yang masih aktif, saat ada nozzle tersumbat yang gagal diperbaiki. Ini adalah fungsi andal yang memastikan pengoperasian tetap berjalan lancar tanpa gangguan

Media roll balance management

“Media Tracker”

Fitur “Media Tracker” mengelola sisa media dengan mencetak barcode sebelum gulungan yang sedang digunakan dilepas. Sistem akan membaca barcode tersebut saat gulungan dipasang kembali. Hal ini menyederhanakan manajemen sisa kapasitas untuk berbagai jenis media.

Unit Pengecekan Nozzle Otomatis (opsional)

*Fungsi ini tidak menjamin keakuratan deteksi yang sempurna

Penanganan dan transportasi media yang unggul

Pengaturan PG 4 langkah

Pengaturan PG 4 langkah yang disempurnakan memungkinkan operator memilih ketinggian print head yang optimal untuk media yang digunakan. Hal ini mengurangi risiko kontak print head dan menjaga kualitas cetak tetap stabil

Mekanisme penekan multi-tahap

Daya pasokan media dipengaruhi oleh tekanan dan ketebalan bahan. Mode tekanan ini dapat diatur ke empat tingkatan: tinggi, sedang, rendah, dan tekanan parsial, dengan menyesuaikan posisi tuas pengaturan media dan lengan penekan, yang akan memperluas kemampuan pasokan media. Kertas tipis dan media yang lembut, yang sebelumnya tidak dapat diumpan oleh mesin solven konvensional, kini dapat didukung dengan mengatur tekanan ke tingkat rendah. Selain itu, pengerutan media (cockling) dapat diminimalkan dengan menonaktifkan beberapa rol penekan secara individual.

Tuas Pengaturan Media

Lengan Penekan

MUTOH Status Monitor(MSM)

MUTOH Status Monitor adalah perangkat lunak (software) yang memungkinkan pengecekan status pengoperasian printer dari komputer secara real time.

Informasi berikut dapat diperiksa pada printer MUTOH Anda:

- Informasi Detail

- Informasi Status

- Informasi Pemanas (Heater)

- Informasi Suhu Print Head & Kartrid

- Informasi Kartu S/C (Smart Card)

- Informasi Cetak dan Riwayat Cetak (informasi pekerjaan, waktu cetak, konsumsi tinta, biaya, dll.)

Specifications

| Printer Model | XPJ-1682SR Pro | |

|---|---|---|

| Print head | Print method | On-demand piezo drive system |

| Head height | Low1: 1.5mm / Low 2: 2.0mm / Middle: 2.5mm / High: 4.0mm | |

| Number | 2 | |

| Media | Roll media width | Maximum: 1,625mm Minimum: 500mm |

| Maximum media thickness | Low1: 0.3mm / Low2: 0.8mm / Middle: 1.3mm / High: 2.8mm * 1mm or less is recommended. | |

| Diameter | Φ200mm or less | |

| Core diameter | 2 inches or 3 inches | |

| Weight | 30kg or less | |

| Maximum printable width | 1,615mm | |

| Maximum printable length | 1,500m | |

| Ink | Type | NT Ink 6000 SB |

| Color | 4 colors (C, M, Y, K) / 8 color (C, M, Y, K, Lc, Lm, Lk, Or) | |

| Capacity | 1,000ml bag | |

| Print resolution | Maximum 1200dpi | |

| Interface | Gb-Ethernet (1000BASE-T) | |

| Power supply | Voltage: AC 100V~120V ±10% / AC 200V~240V ±10% Frequency: 50/60Hz ±1Hz | |

| Environmental condition | Printer operation | Temperature: 20°C~32°C Humidity: 40%~60% No condensing |

| Accuracy guaranteed | Temperature: 22°C~30°C Humidity: 40%~60% No condensing | |

| Power consumption | Operation | AC100V~120V/AC200V~240V, 1,100W or less |

| Sleep mode | AC100V~120V/AC200V~240V, 30W or less | |

| External dimensions (W)x(D)x(H) | Printer with stand: 2,770mm x 895mm x 1,428mm (when cover closed) / 1,527mm (when cover opened) When ink case is installed: 2,770mm x 895mm x 1,611mm | |

| Weight | Printer: 141kg Stand: 32kg | |

| RIP Software | Topaz RIP X1 | |

*Specifications are subject to change without notice.

| Nama perusahaan dan produk yang disebutkan adalah merek dagang atau merek dagang terdaftar. Spesifikasi dan tampilan luar produk dapat berubah sewaktu-waktu tanpa pemberitahuan sebelumnya sebagai akibat dari peningkatan produk atau alasan terkait lainnya. |