Valuejet 1948WX

The MUTOH XpertJet series, which delivers excellent print quality and high productivity, now has a 54”/1.3m wide eco solvent

print perfectly balancing cost and performance.

Rp 460,000,000

*Harga sewaktu-waktu dapat berubah tanpa pemberitahuan terlebih dahulu.

*Ongkos kirim GRATIS untuk pembelian mesin digital printing wilayah Jabodetabek.

*Setiap pembelian produk di PT NanoSNG, harga yang tertera sudah termasuk pajak, sehingga Anda tidak perlu khawatir dengan biaya tambahan.

Open a new era of high production Dye-Sublimation Printing

The ValueJet 1948WX, high speed dye-sublimation inkjet printer effortlessly delivers the best-in-class speed and superior print quality.

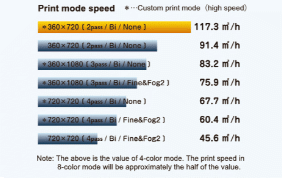

Staggered 4 print head-setup enables high-speed printing and improved productivity, the VJ-1948WX achieves a maximum print speed of 117.3m²/h*.

With the addition of new custom modes, the options of the printing function are significantly widened.

The large dual heaters are incorporate on the rear side of the front paper guides, and it provides fast dry times and accelerates production speeds.

The MUTOH original dye-sublimation transfer ink (DH21) provides optimum print quality and wide color gamut. The DH21 ink is available in a 4-color configuration CMYK and 7-color (CMYK, LC, LM, LK). Large capacity ink bags (1,000ml or 2,200ml) with the original ink cases support prolonged continuous printing. A special feature of the MUTOH Status Monitor (MSM), the ValueJet Print Server (VPS) provides high-speed and stable printing. Creates scarves, blankets, promotional items, trade show graphics, flags, banners, custom interior designs, apparel, sports uniforms and more.

*at 360x720dpi

Features:

MUTOH dye-sublimation ink“DH21”

Staggered 4 print heads

Variable Dot Technology

3 steps head height adjustment

Built-in large dual heaters

Pressure roller down system

- Equipped the automatic cutting function

- Feed and take-up system included (up to 100kg)

- Easy daily maintenance

Application:

Banners

Signage

Sticker

Table Display

Window Decals

Wraps

Staggered 4-printhead design

Staggered 4-head design enables high-speed printing and improved productivity. The VJ-1948WX achieves a maximum print speed of 17.3 m2 per hour. Printhead select function is available to be printed. Without using impaired printheads, it keeps printing with the remaining printheads, and provides reliable business support. And also VJ-1948WX minimizes the ink consumption by selecting a printhead to perform head cleaning.

Built-in large dual heaters

Built-in large dual heaters provide fast dry times for increased production speeds.

They are incorporated on the rear side of the front paper guide. Each heater’s temperature can be set from the control panel individually, and checked or changed anytime without interrupting the printing operation.

Heavy-duty take-up system included

A heavy-duty feed and take-up system maintains stable media transportation up to 100kg. It also supports 70gsm/m2 standard transfer papers to 130 gsm/m2 thicker and heavier transfer papers. Even a 45 gsm/m2 very thin transfer paper can be supported by setting the conditions of the weight, countermeasure of cockling, adsorption fans, etc.

As the printed media are winded with the constant pressure, they can be easily used in the post heat-press processing stage.

*It also can be set on VJ-1948WX as option.

MUTOH original dye-sublimation ink

MUTOH’a original dye-sublimation ink in 4 colors (K, C ,M, Y) and 8 colors (K, C, L, M, Lc, Lm, Lk) delivers optimal print quality and wide color gamut. The large capacity ink bags support various business purposes with prolonged continuous printing.

<MUTOH original odorless both during the printing and the transfer process>

- Does not require any hazardous marks, and is highly environment and human body safe.

- Practically odorless both during the printing and the transfer process

- Excellent nozzle stability for high speed and high volume printing, and offers optimal print quality and wide color gamut.

- High washing fastness and perspiration resistance

- Allows directly print* on the textile without using transfer paper

*please use pre-treated media

High image quality with variable dot technology

3 kinds of variable dot produce fine texture and color representation. With using different diameters of large, middle and small sizes, they can express the gradation smoothly and brilliant color.

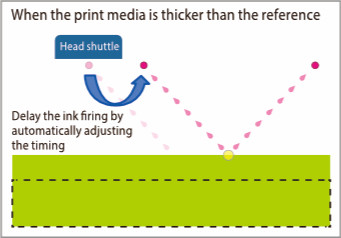

DropMaster Technology

By inputing different media thickness on the registered media setting, Drop Master Technology is capable of automatically recalculating and adjusting the bi-directional drop fire timings. It achieves smooth high-quality printing.

Intellegent interweave

Intelligent interweave offers many printing effects to improve the image quality. They allow the reduction and elimination of banding and color unevenness.

*The effect may not be suitable for high-speed printing. Please test in advance.

Wave Print

Fuzz Print

Designed with advanced features

- The pressure roller hold down system is equipped in both the front and rear side of the printer, and ensures easy handling ny the manual lever from either of two locations. There are two pressure setting “standard” and “strong”.

- The pressure rollers can be raised up and down individually even when printing on thin transfer paper to avoid cockling.

The head height can be adjusted in three steps : 1.5mm, 2.5mm, and 4.0mm. Each can also be activated for auto-cleaning.

MUTOH Status Monitor (MSM)

- Significant improvement of response time for print status acquisition

- Support initial installation wizard

- Support 10 languages for all functions.

It requires user registration to download MSM.

https://club.mutoh.co.jp/mutoh/guser/

Specifications

| Model Name | VJ-1948 WX | |

|---|---|---|

| Print Technology | Drop-on-demand Micro Piezo Inkjet Technology | |

| Print Head | 4 (staggered setup) | |

| Head Heights | Low:1.5mm / Middle:2.5mm / High: 4.0mm | |

| Max. Media Width | 1910mm | |

| Max. Print Width | 1900mm | |

| Ink | Type | Water-based dye sublimation ink (NT Ink) |

| Ink set | 4-color (Black, Cyan, Magenta, Yellow) 7-color (Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta, Light Black) | |

| Volume | 1,000ml bottle | |

| No. of slot | 8 | |

| Print Resolutions | 1440/1080/720/360dpi (10 modes as standard + 19 modes as custom) | |

| Interface | Gigabit-Ethernet(1000BASE-T) | |

| Media Measurements* | φ150mm/ 2″ & 3″ / 30kg or less | |

| Heater Control System | Heaters(30-50℃), OFF | |

| Power Supply | AC 100-120V/AC 200-240V – 60/50 Hz | |

| A-property Acoustic Power Level (Actual Measured Value) | 69.8dB or less | |

| Printer Accuracy Guaranteed Environment | Temperature: 20~30℃ Humidity: 40~60%RH (Non Condensing) | |

| Power Consumption | Operating Status:600W or less, In standby: 91W or less | |

| Machine Measurements | W2983 x D966 x H1261mm (including a stand) | |

| W2983 x D1334 x H1261 mm (including a stand + feed and take-up system) | ||

| Packing Size | Printer: W3165 x D1150 x H900mm, Weight: 268kg | |

| Stand: W2462 x D395 x H250mm, Weight: 42kg | ||

| Feed and take-up system (100kg): W2780 x D1080 x H433mm, Weight: 159kg | ||

| Weight | printer: 164kg Stand: 37kg Feed and take-up system: 89kg | |

| Optional | Feed and take-up sysetem VJ-19TUP100 (100kg) | |

| Take-up system VJ-16/19TUP30 (30kg) | ||

| 1000ml/2200ml ink bag case | ||

| Cutter blade VJ-CB | ||

*Due to the removal of the flange joint, the 2-inch media core can be adjusted; however, do not use the solid 2-inch core media.