Xpertjet 1341WR Pro

*Harga sewaktu-waktu dapat berubah tanpa pemberitahuan terlebih dahulu.

*Ongkos kirim GRATIS untuk pembelian mesin digital printing wilayah Jabodetabek.

*Setiap pembelian produk di PT NanoSNG, harga yang tertera sudah termasuk pajak, sehingga Anda tidak perlu khawatir dengan biaya tambahan.

A 54-inch compact model designed for high image quality and user convenience

The MUTOH original dye-sublimation ink provides superior media transfer, achieves high density colors with less ink consumption. The fast ink drying enables printings on thinner/lighter transfer papers, and excellent jetting performance and color stability provide high-quality output.

The XpertJet 1341WR Pro is an ideal printer for trade show graphics, flags, banners, custom interior design, apparel, custom merchandise and more.

Application:

Apparel

Poster

Tradeshow

Flags

Personal items

Interior Decor

Print technologies for high productivity and high image quality

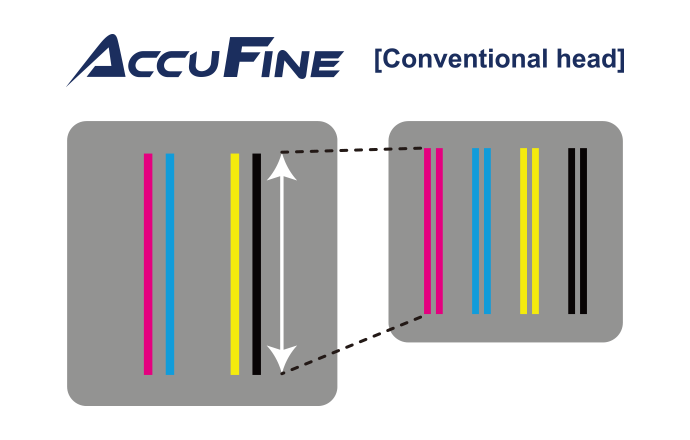

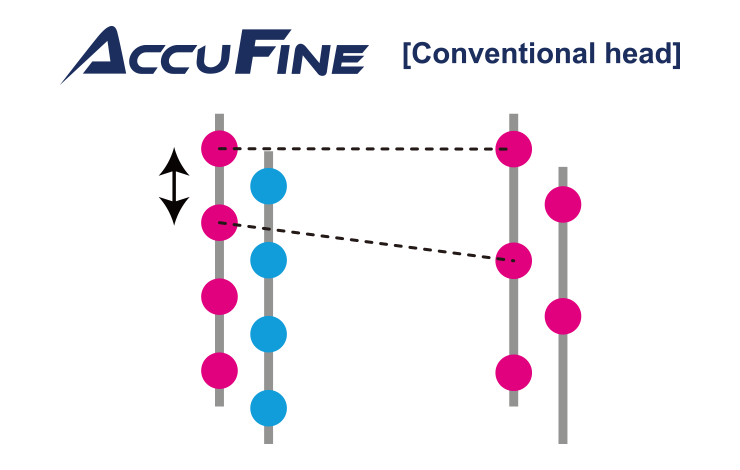

Increased nozzle row length

High density nozzle pitch

Contributes to higher image quality

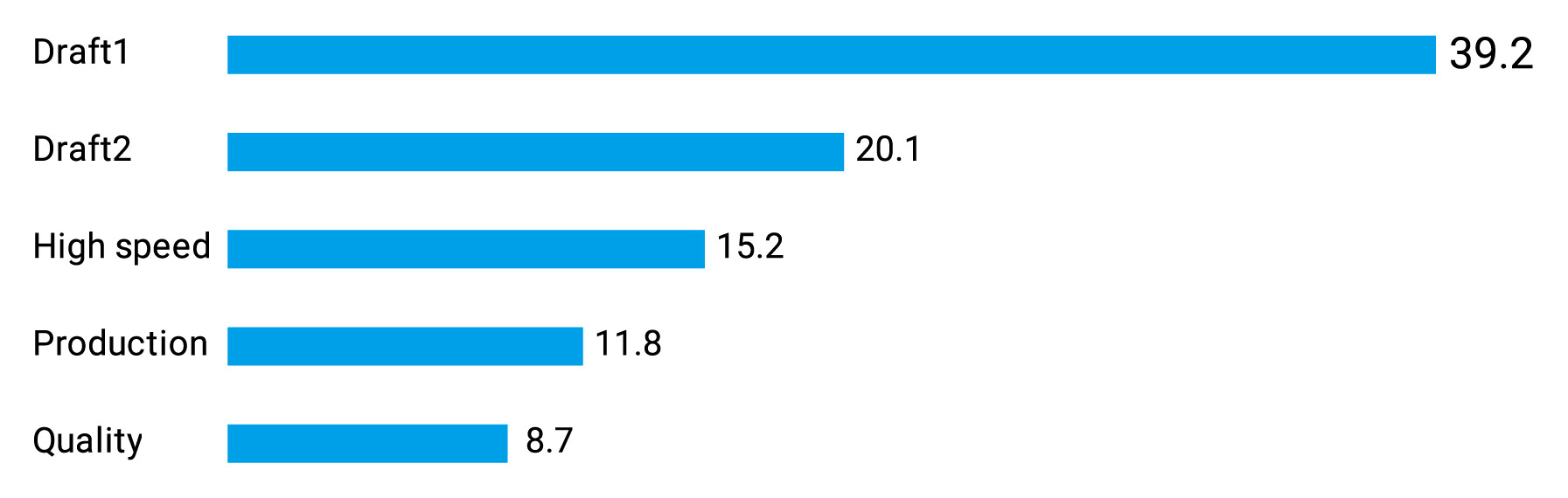

◆ Throughput of XpertJet 1341WR Pro (m2/h)

New print effect “i-screen” on board

By arranging the dots in a way that takes into account how they look, this reduces banding for smoother print images.

MUTOH’s unique technologies for automation and efficiency

Automatic Bi-D adjustment

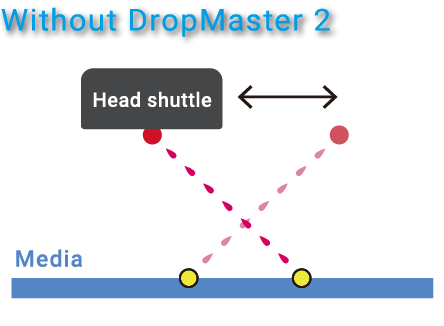

“DropMaster 2”

Automatic media feed adjustment

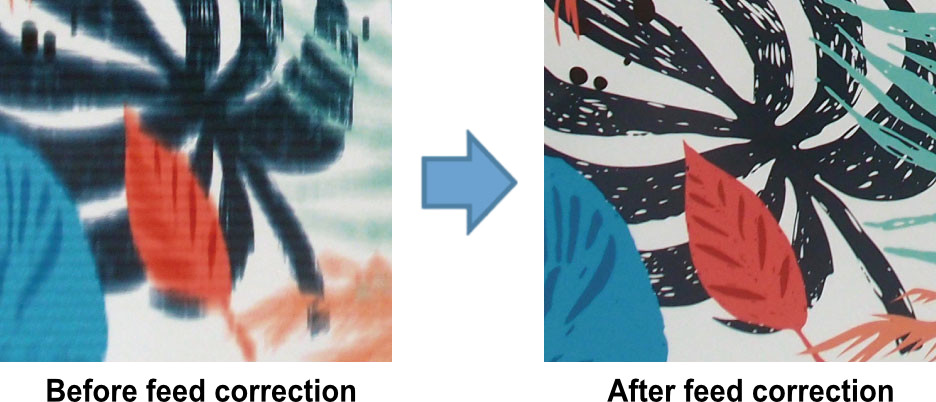

“FEED MASTER”

Nozzle selection Function

“Nozzle Area Select”

Media roll balance management

“Media Tracker”

High media compatibility

Three head height settings

Partial pressure cancel mechanism

Media feeding and take-up units (optional)

Edge holder (optional)

Easy maintenance

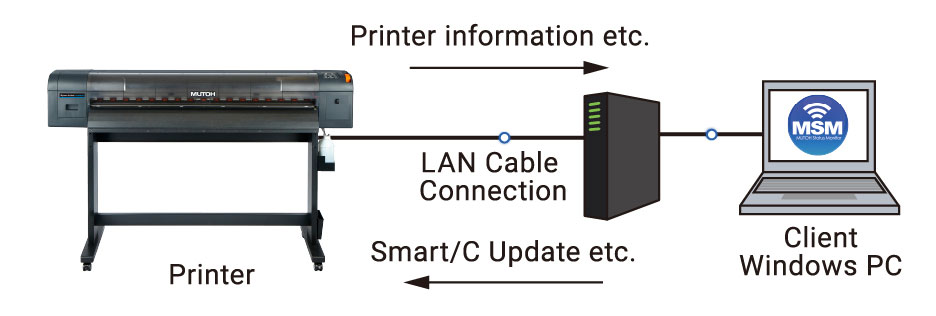

MUTOH Status Monitor(MSM)

- Detailed information Status information

- Heater information

- Head temperature/cartridge information

- S/C card information

- Paper information Print information Print history, etc.

- Multi-language support for all functions (10 languages)

- Print history can be exported as a CSV file.

Specifications

| Model Name | XPJ-1341WR-P | |

|---|---|---|

| Print Technology | Drop-on-demand Micro Piezo Inkjet Technology | |

| Print Head | 2 (staggered setup) | |

| Head Heights | Four-level adjustment of Low 1: 1.5mm, Low 2: 2.0mm, Mid.: 2.5mm, High: 4.0mm | |

| Media | Width | Maximum 1625mm Minimum 500mm |

| Thickness | 0.04~1.0mm | |

| Measurement | Ø 150 mm / 2” & 3” / 30 kg or less | |

| Maximum Printable Width | 1615mm | |

| Maximum Print Length | 1500mm | |

| Ink | Type | Water-based dye sublimation ink (NT Ink) |

| Ink set | 4-color (Black, Cyan, Magenta, Yellow) | |

| Volume | 1,000ml bottle | |

| No. of slot | 4 | |

| Maximum Print Resolution | 1200dpi | |

| Interface | Gb-Ethernet (1000BASE-T) | |

| Power Requirements | Voltage: AC 100V~120V ±10% / AC 200V~240V ±10% Frequency: 50/60Hz ±1Hz | |

| Noise | Printing: 70.4 dB Standby: 64.2 dB | |

| Printable Environment | Printer Operation | Temperature: 20℃~32℃ Humidity: 40%~60% No condensing |

| Accuracy Guaranteed | Temperature: 22℃~30℃ Humidity: 40%~60% No condensiing | |

| Printer Dimensions (WxDxH) | Main body: 2770mm x 895mm x 1428mm (cover closed) / (when installing 2200ml ink bag cases: 1712mm) | |

| Printer Weight | Main body: 137kg Stand: 32kg | |

| Optional | Take-up Unit | Supported media weight up to 30kg |

| Take-up Unit | Supported media weight up to 40kg | |

| Take-up Unit | Supported media weight up to 100kg/220lbs | |

| Roll Media Flange | Torque:1kgf.cm 1 piece/box | |

| Roll Media Flange_High Torque | Torque:4kgf.cm 1 piece/box | |

| 2200ml Ink Bag Case | Supported ink bag: 1000ml / 2200ml 4 cases/box | |

| 1000ml Ink Bag Case | Supported ink bag: 1000ml 4 cases/box | |

| Ink Tube Connector | 4 pieces /box | |

| Cutter Blade | Replacement cutter blade | |

|

The name of company and products mentioned are trademarks or registered trademarks. Specifications and outward appearances of any product therein may be changed without notice as a result of product improvement or other related reasons. |